Maquinaria

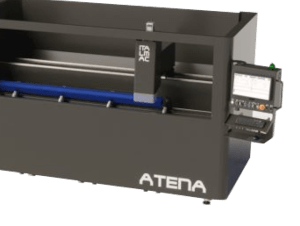

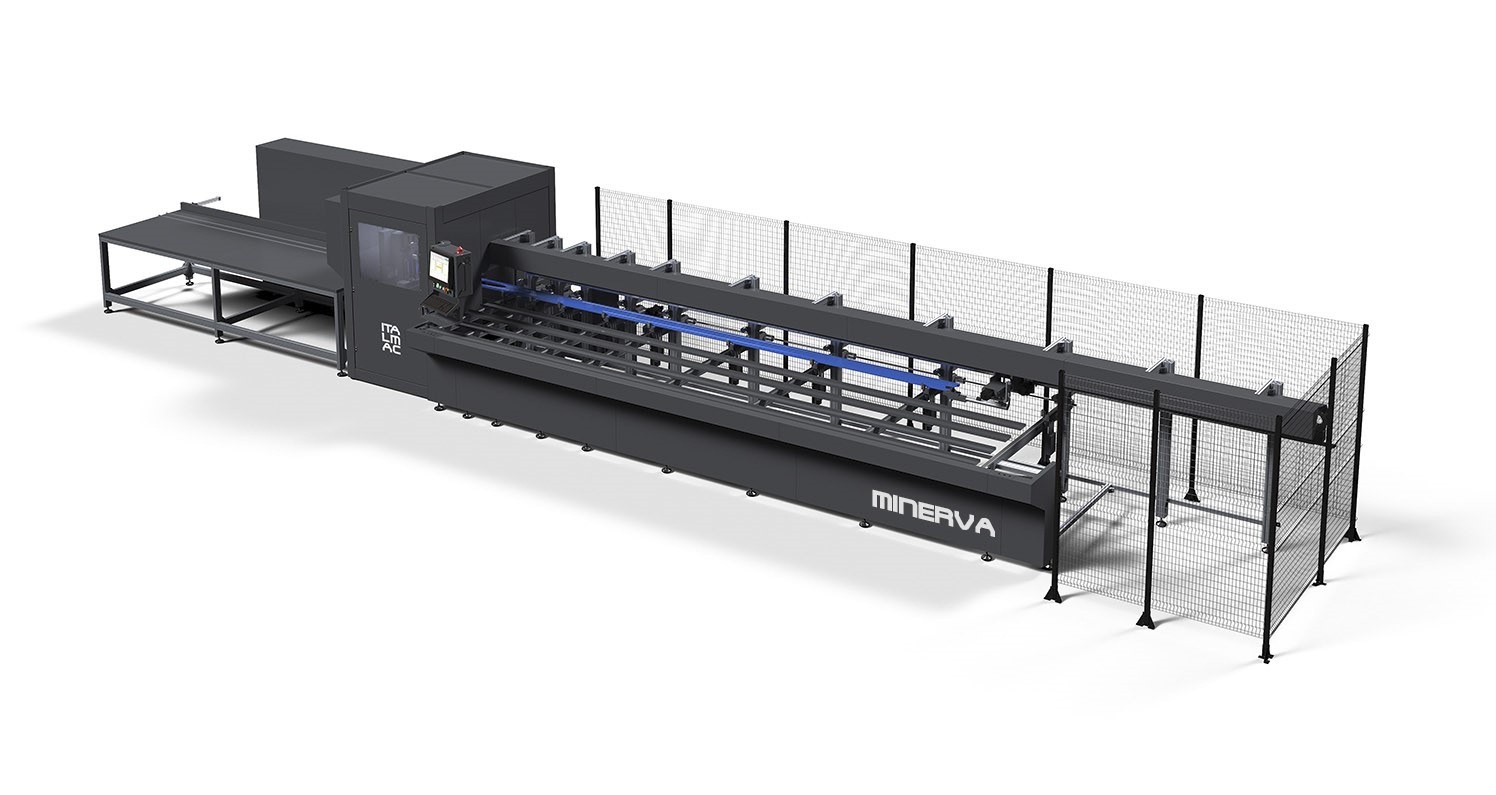

Maquinaria para aluminio, PVC, hierro, vidrio, madera y otros

Logística

Fabricación y diseño de distribuciones logísticas dentro de las instalaciones

Sat

Servicio técnico para maquinaria industrial

Fabricación

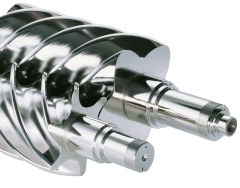

Fabricamos nuestra propia marca Strong Bull

Sectores

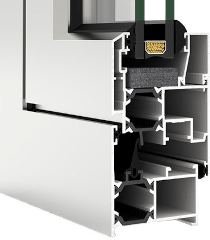

Maquinaria para Aluminio, PVC e Industrial

APD Maqmaster se ha convertido en un referente en el mundo de la maquinaria industrial.

Aunque nuestros orígenes fueron en el sector del aluminio y el PVC, como podrás comprobar, hoy día, atendemos prácticamente todos los sectores de la industria.

Maquinaria

Venta de Maquinaria industrial

Las mejores marcas a tu alcance, con el mejor soporte técnico y toda la experiencia de ser fabricantes.

Más de 30 años vendiendo maquinaria para Aluminio, PVC e Industrial.

Fabricantes maquinaria

Experiencia, profesionalidad y soporte técnico

APD Maqmaster lleva más de 30 años vendiendo y fabricando maquinaria para aluminio, PVC e industrial tanto para España como para el resto del mundo.